Live Labs Blog: a final view from Cumbria

Cumbria's Matt Waning provides the final round up from the plastic roads Live Lab

Embedding innovation into routine and planned maintenance can be problematic and this is sometimes used as an argument to restrict initiatives. Cumbria County Council (CCC), however, recognise that innovation is vital for the development of asset management solutions that meet stakeholder demand and deliver the service within an agreed budget.

According to the UN Environment, more than eight billion tonnes of plastic has been produced since the early 1950s, and around 60% has ended up in landfill or the environment. Despite the environmental risks associated with plastics and packaging, the construction industry is the second largest consumer of plastic in the UK (Innovation Today, March 2019).

With this in mind, CCC identified an opportunity to investigate the benefits of using plastic waste as an additive in the production of the bituminous pavement materials that it uses in its highway maintenance works across all parts of the county’s highways network. The initiative was developed following an offer by MacRebur (a local SME) to supply a new additive, developed from processing plastic waste, for use in materials used for surfacing work.

CCC have worked with MacRebur for around four years now, but had never had the financial freedom to look at academic work, extended monitoring, multiple material testing and so forth. Our involvement in the Live Labs programme has allowed us to do this, working with the University or Nottingham and PTS to closely inspect and scrutinise the detail with great success. As the project progressed, CCC were approached by surfacing partner Hanson Contracting to trial a waste plastic derived additive from their bitumen supplier, Shell.

The Live Labs programme has provided several successful and satisfying experiences at a project level but also a wider corporate level.

A key success of the project has been the provision of a fully independent research report. WSP have collated a huge library of existing information from partners and existing international research to show the gaps that have needed filling. They have gone on to develop site selection criteria, testing requirements and design options to pull together all the information possible within the budgetary and time constraints.

The literature review highlighted that the scientific and engineering understanding of using recycled plastic is still at an early stage and more research is required. In general, the literature review demonstrated that most research is laboratory based, with insufficient technical information from studies based on the in-service performance of pavements.

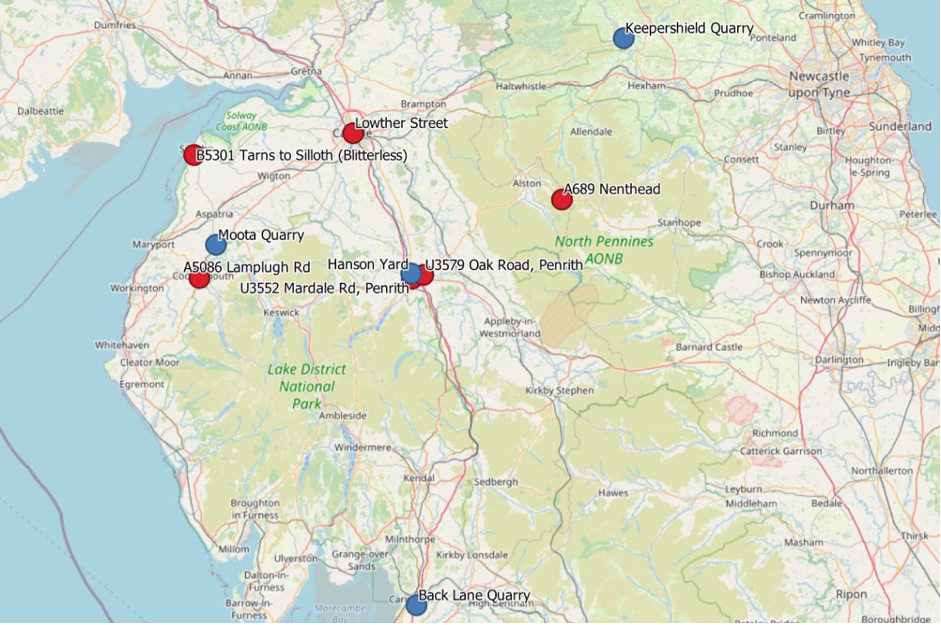

Road trials have proved to be an excellent way to evaluate the performance of new materials. The project undertook six live road trials and four quarry trials, (seen in the map below). There is a five-year monitoring and inspection programme in place to allow CCC to continue to feed into the Live Labs library.

From our involvement in the programme we have a number of ‘lessons learned’ and advice for other authorities keen to try incorporating innovation into their projects:

- Don’t leave it too late to speak to others. A common theme throughout all projects in the Live Labs programme has been legal and procurement challenges, and Cumbria has been no different. Working with suppliers outside of existing frameworks, who aren’t on financial systems, have no contractual agreements or detailed knowledge of procurement and legal obligations has been perhaps the most challenging aspect of the last two years. Getting together early to share these problems would have helped to minimise disruption. Once these issues were discussed at programme level, other authorities, ADEPT and DfT shared tips and experience speeding up some of the processes.

- Don’t be afraid to add in new ideas and to accept scope creep as time moves on but keep communication clear. Over a two-year project, products, technology, social and economic desire can change. Over the programme we have added ideas, amended objectives and changed or added partners. Whilst this isn’t a problem in itself, we misjudged supply chain experience in project change and as a result didn’t communicate intentions and reasons for scope creep clearly enough.

- Don’t underestimate the importance of clear concise communication no matter how seemingly trivial - there can be a lack of experience between public and private parties and so huge problems can come from missing what can be seen as the small details.

Being part of the Live Labs programme has made CCC has brought many benefits. We have been made aware of initiatives from other labs which could contribute towards our decarbonisation goals, such as composite lighting columns. It has also opened up innovation and decarbonisation partnerships which will extend beyond Live Labs 1 and hopefully help us become part of Live Labs 2.